Coal & LDO Analysis

Coal & LDO Analysis

The range of coal and coke tests carried out in a furnace or oven has grown over many years, and Carbolite Gero has responded to the requirements of each new standard by designing a furnace to suit the specific requirements of each test method.

Moisture

Coal moisture is important for handling as well as downstream circuits and there are penalties involved with higher moisture. Therefore, it becomes important to use and quote the correct moisture terms.

Volatile Matter

Volatile matter is one of the most common parameters measured in coal. It is part of a standard proximate analysis. Volatile matter is essentially a measure of the nonwater gases formed from a coal sample during heating. It is measured as the weight percent of gas (emissions) from a coal sample that is released during heating to 950 C° in an oxygen-free environment , except for moisture (which will evaporate as water vapor), at a standardized temperature. Volatile matter is measured directly in the automated proximate analyzer. Results are presented in weight percent.

Sulfur

Sulfur in the ultimate analysis is the measured weight percent of sulfur in the coal. It is determined by ASTM methods D5373-08, or D4239-02. In the test, a coal sample is ground to a set size and weighed, then placed in a sulfur analyzer. In the analyzer, the sample is combusted at a temperature of 1,370°C in an oxygen atmosphere. The oxygen reacts with sulfur to form sulfur dioxide gas. The gas passes through an infrared absorption detector in the analyzer, which measures the concentration of sulfur.

Flash Point

Flash point is the lowest temperature of the test specimen, corrected to a barometric pressure of 101.3 kPa, at which the application of an ignition source causes the vapor of the test specimen to ignite momentarily and the flame to propagate across the surface of the liquid under the specified conditions of test.

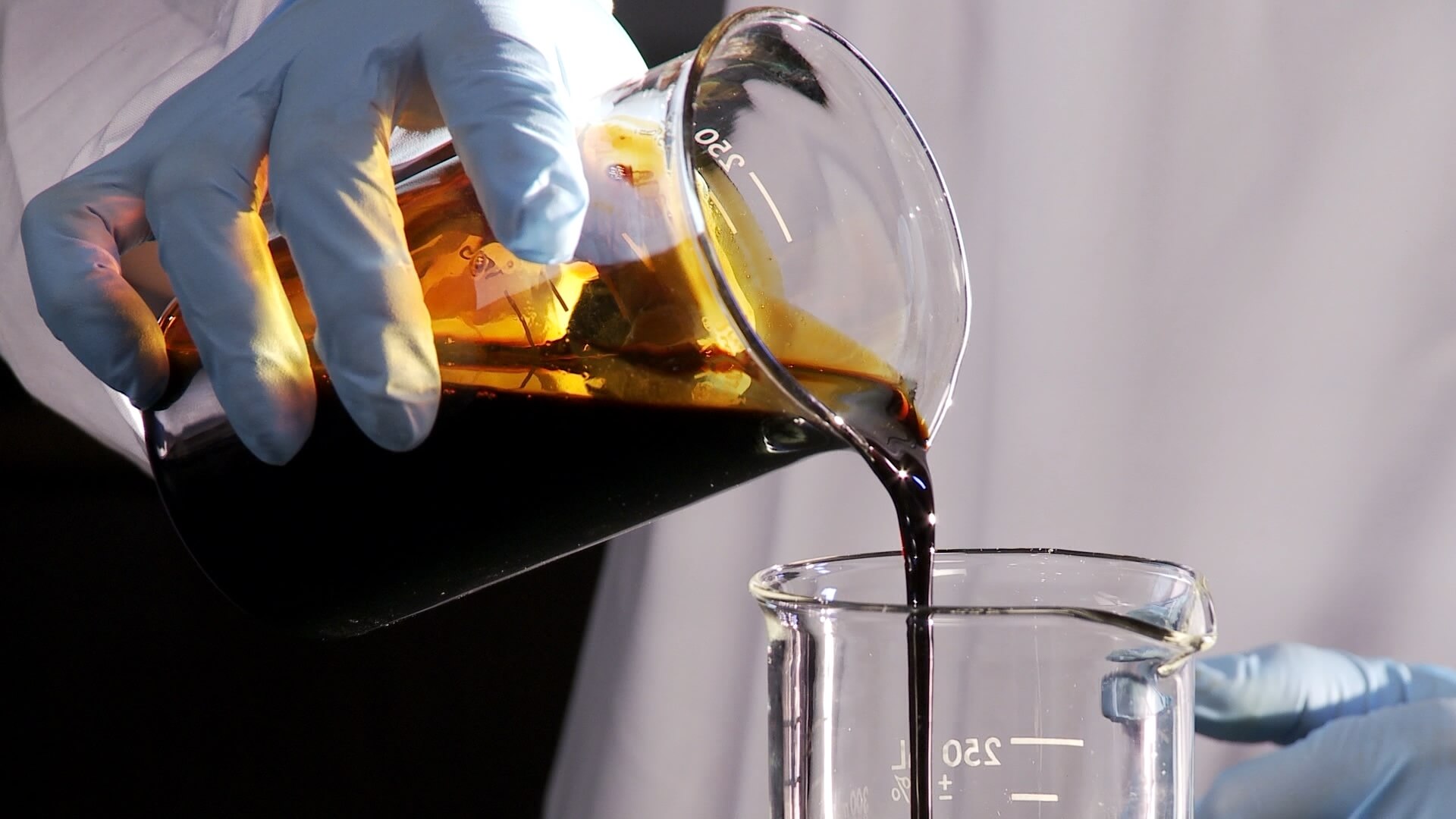

Viscosity

Fuels, as for any other type of substance, can be assigned some physical and chemical properties (e.g. density, thermal capacity, vapour pressure, chemical formula, etc. However, most of the times, combustion properties are also assigned to fuels, in spite of the fact that these properties depend on the oxidiser and the actual process. Fuel price, availability, risk, and so on, could also be considered fuel properties.

Density

Density. Knowledge of the physical properties of coal is important in coal preparation and utilization. For example, coal density ranges from approximately 1.1 to about 1.5 megagrams per cubic metre, or grams per cubic centimetre.

Carbon Content

Testing for carbon content in biofuels, petroleum products, crude oil, and lubricants is available through Intertek laboratories on a global basis. Carbon content analysis of hydrocarbons is provided for quality control, research, troubleshooting, and compliance testing requirements. Determination of carbon content is performed using the ASTM D5291 test method, among other methods.

Copper Streep Number

The Copper Strip Tarnish Test assesses the relative degree of corrosively of petroleum products, including aviation fuels, automotive gasoline, natural gasoline, solvents, kerosene, diesel fuel, distillate fuel oil, lubricating oil and other products. A polished copper strip is immersed in 30mL of sample at elevated temperature.

Pour Point

The sample is periodically examined while it is being cooled in the cloud and pour point apparatus. The highest temperature at which haziness is observed (cloud point), or the lowest temperature at which movement of the oil is observed (pour point), is reported as the test result.